According to the requirements of GB 3836 standard for explosion-proof electrical equipment, the explosion-proof marking of explosion-proof electrical equipment includes: explosion-proof type+equipment category+(gas group)+temperature group

1. Explosion proof type

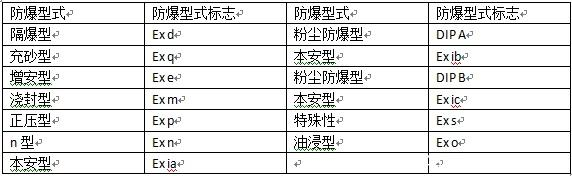

According to the explosion-proof measures taken, explosion-proof electrical equipment can be classified into explosion-proof type, increased safety type, intrinsic safety type, positive pressure type, oil immersed type, sand filled type, poured sealing type, n-type, special type, dust explosion-proof type, etc. Their identification is shown in the table below< br />

2. The vast majority of petrochemical enterprises belong to flammable and explosive mixed gas environments, and the explosion-proof type of explosion-proof electrical equipment generally requires intrinsic safety to meet the requirements< br />

Electrical equipment used in explosive gas environments is divided into:

Class I: Electrical equipment used underground in coal mines< br />

Class II: Electrical equipment used in explosive gas environments other than coal mines< br />

Class II explosion-proof type "d" and intrinsic safety type "i" electrical equipment are further divided into IIA, IIB, and IIC categories< br />

Electrical equipment used in environments with combustible dust is divided into:

A-type dust tight equipment; B-type dust tight equipment; A-type dust-proof equipment; B-type dust-proof equipment< br />

So, the equipment categories for explosion-proof mobile phones in petrochemical enterprises are generally essential safety types IIA, IIB, and IIC, and IIC on the market can meet the requirements of most chemical plants< br />

3. Gas group

The explosive transmission ability of explosive gas mixtures indicates the level of their explosive danger. The greater the explosive transmission ability of explosive mixtures, the higher their danger. The explosive transmission capacity of explosive mixtures can be represented by the maximum test safety gap. At the same time, the difficulty of igniting explosive gases, liquid vapors, and mists also indicates the level of their explosion hazard, which is represented by the minimum ignition current ratio. Class II explosion-proof electrical equipment or intrinsic safety electrical equipment is further classified into IIA, IIB, and IIC according to their maximum test safety gap or minimum ignition current ratio applicable to explosive gas mixtures< br />

4. Temperature group

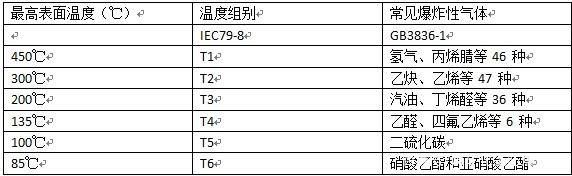

The ignition temperature of explosive gas mixtures is the temperature limit at which they can be ignited. Electrical equipment is divided into groups T1-T6 according to its highest surface temperature, so that the highest surface temperature of the corresponding electrical equipment in groups T1-T6 cannot exceed the allowable value of the corresponding temperature group. The relationship between temperature group, equipment surface temperature, and ignition temperature of flammable gases or vapors is shown in the following table< br />

2、 In summary, petrochemical companies choose explosion-proof mobile phones that meet their own conditions< br />

There are generally three types of explosion-proof mobile phones on the market: 5G explosion-proof mobile phones, explosion-proof function mobile phones, explosion-proof smartphones, and explosion-proof intercom mobile phones. The appearance is not much different from a regular mobile phone. Here is an example of an explosion-proof mobile phone from Shenzhen Wanwei Communication Technology Co., Ltd.

VANVE World Wide Communication A25: World Wide Communication 5G Explosion proof Terminal \ 5G Explosion proof Smartphone \ 5G Explosion proof Interphone \ 5G Edge

Calculate explosion-proof terminals

Application case of Wanwei communication explosion-proof terminal in the chemical industry:

1. Hainan Refining and Chemical Explosion proof Terminal

2. Southwest Oil and Gas Production Stations

3. CNOOC Huizhou

4. PetroChina, Sinopec, CNOOC, CPC BP

5. Huiwei Gas, Dapeng Natural Gas, PetroChina Kunlun Gas, Qian'ang Gas, etc

chat me